The Sustainable Communities and Waste (SCaW) Hub is working to reduce the environmental impact of tyres during their use and promote safe remanufacture at the end of their lifetime. The Hub is driving outcomes through multiple pathways with effective co-design and collaboration with various partners.

Partnering with Tyre Stewardship Australia

SCaW Hub is collaborating with Tyre Stewardship Australia (TSA) to limit the environmental effects of end-of-life tyres and promote safe reuse in products made from recycled rubber materials. The organisation brings together representatives from across the supply chain including tyre retailers, manufacturers, recyclers and collectors.

One of TSA’s key strategies to achieve impact is increasing the recovery rate of waste tyres and the development of end markets for these materials. Transforming a waste stream into a useful commodity creates new industries and employment opportunities while reducing the environmental harm caused by the illegal dumping of end-of-life tyres.

TSA’s strategy aligns with several of SCaW's impact priorities (IPs) that arose from extensive stakeholder engagement at the beginning of the Hub. The organisation is also considered a key stakeholder of three IPs.

IP2: Understanding microplastics generated from tyre wear

The IP2: Plastics and other waste materials project is working to better understand microplastics and reduce the effects of these particles on the environment. The team is co-led by Hub leader Scientia Professor Veena Sahajwalla and Anirban Ghose and includes Dr Rumana Hossain and Dr Samane Maroufi from UNSW Sydney.

The particles generated by wear of tyres during their lifetime use is one of the key focus areas of the research. Preliminary analysis has shown microparticles from tyre dust are present as pollutants in samples collected from storm water drain filters. Better understanding the characteristics of tyre wear particles in these environments is an essential gap that must be bridged for effective management of this issue.

The project will run a study of particles generated by tyre wear to understand better ways of reducing the impact of microplastics before they enter waterways.

IP3: Safe reuse of end-of-life tyres

The IP3: Hazardous Waste and Materials project has a focus on chemicals of concern in waste and generating reliable data for managing waste and reuse products. Key to this has been designing robust waste sampling guidelines for complex waste materials to ensure stakeholders can understand what’s in our waste.

The research team, comprising of researchers from CSIRO, Monash and Curtin Universities, and UNSW, as well as partners from DCCEEW, NSW DCCEEW, Victoria EPA and industry, have co-designed a robust and transferrable sampling guidance for complex waste materials to ensure that data generated from characterisation is high-quality and relevant for Australian waste management, recycling and reuse scenarios. It has been designed to be used with confidence by decision makers when assessing the presence and risk of chemicals identified in wastes and waste derived materials.

The guidance uses end-of-life tyres and recycled rubber products as case studies for the development of the guidance document, which will be iteratively updated as other waste materials are investigated. The data and information generated from sampling and characterising end-of-life tyres and recycled rubber products can inform market development for recycled products and better product design, whilst identifying the risk of chemicals on environmental and human health.

The team has compiled chemical data on what’s in tyre materials and has undertaken water leaching trials to assess what might be released from tyres and tyre reuse products.

Dr Boxall co-presented this work at the 2024 NESP Partnership, Science, Impact conference alongside research user and Principal Regulatory Scientist Glen Walker from DCCEEW. The presentation detailed the Hub’s work on ‘Co-designing research for a safer circular economy.’

IP5: Improving the circularity of tyres

Managing end-of-life tyres is a challenge across Australia. But the issue disproportionately affects regional and remote areas where significant volumes of tyres are generated and disposed of by mining and other industries. Tyres have, therefore, become a strong focus of the SCaW Hub because of its thematic focus areas: Regional and Remote Solutions and Waste Resources.

Tyre waste generators often have little incentive to effectively manage end-of-life tyres for resource recovery. In the first stage of the project, Dr Anna Kaksonen, Dr Naomi Boxall and Dr Ka Yu Cheng from CSIRO collaborated with Steve Tobin, Dr Roberto Minunno and Dr Atiq Zaman from Curtin University on research exploring ways to improve the circularity of waste tyres, conveyor belts and other rubber materials.

The project was co-funded by the Hub, The Waste Authority of Western Australia, TSA, CSIRO and Curtin University. The project has released the report: Exploring opportunities for increasing value recovery from end-of-life tyres and conveyor belts in Western Australia. The report is also available on the TSA website to encourage access and uptake from its stakeholders.

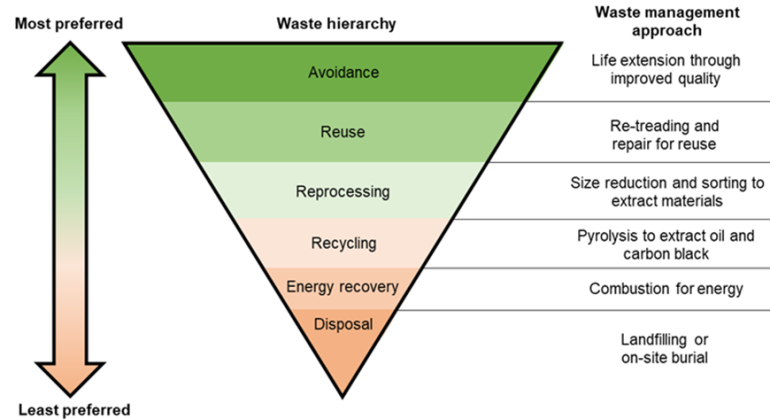

The stage one project identified challenges in managing end-of-life tyres in Western Australia that can be addressed through policy and regulation, though scaling this technology remains a regional challenge. The review also found there are regionally specific opportunities for the development of tyre repair and recycling processes, especially in regional centres that would support resource recovery from mining and other industries in those regions.

In the second stage of the project, Dr Anna Kaksonen, Dr Naomi Boxall and Dr Ka Yu Cheng from CSIRO are collaborating with Dr Benjamin Gazeau, Ana Maria Caceres Ruiz, Dr Roberto Minunno and Dr Atiq Zaman from Curtin University to review best practice case studies for increasing value recovery from end-of-life tyres and conveyor belts in Australia.

Summary

The collaborative efforts of the SCaW Hub in partnership with TSA and DCCEEW are paving the way for a more sustainable approach to managing tyres, tyre dust and end-of-life tyres by reducing their environmental impact. The collaboration is furthering the scientific understanding of how tyres are impacting the environment during their lifetime.

By developing research that helps to improve the understanding of tyre chemicals and dust, increase tyre circularity and implement effective waste sampling, the Hub is driving national and international impact and value through its partnerships. Co-designing research and working closely with stakeholders allows the Hub to address current challenges and shape a safer circular economy for the future. Co-designing research in partnership with TSA will allow the project’s outputs to be fit-for-purpose.